quality

Quick-release fasteners

Secure locking systems for industrial applications

Quick-release fasteners - Series

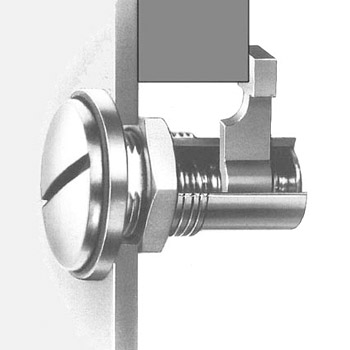

Our quick-release fasteners are easy and safe to use. Opening and closing is done by a quarter turn or a push movement. This means they can be opened and closed quickly – saving time and money.

Camloc quarter-turn fasteners connect components under an elastic preload (frictional connection). Spring elements for generating the preload can be part of the locking pin or the retaining cam. Quarter-turn fasteners are available for tensile loads from 670 N to 10,000 N with a variety of different head shapes.

Select a series:

Series V965L

- Two large clamping ranges (from 1.0 mm to 18.8 mm)

- Simple single-hole mounting – low installation costs

Series V964L

- Large clamping range (up to 15 mm)

- Universally applicable

- Low installation effort due to single-hole mounting

Series V936F

- Max. tensile load 300 N

- Same shaped hole for panel and frame

- Clamping ranges from 2.0 to 4.6 mm

- Quick installation without tools and time expenditure

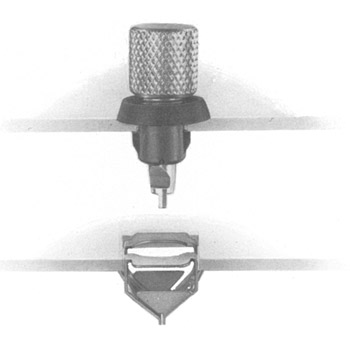

Series 816D – BI-FIX

- Simple and cost-effective installation thanks to clip mounting

- Open with a quarter turn – Close by pressing with a finger

- Due to its small size, it is also particularly suitable for applications in

electrical engineering/electronics.

electrical engineering/electronics.

Series 15F

- Max. tensile load 1330 N

- Quick opening and closing at the touch of a finger

- Simple installation thanks to single-hole mounting

Series 991F

- Max. tensile load 10.000 N

- Closure for maximum tensile load and pretension

- Preferred applications: Commercial vehicles, buses,

agricultural machinery, process engineering, heating systems, etc.

agricultural machinery, process engineering, heating systems, etc.

Series D4002

- Max. tensile load 4700 N

- Small fastener for high tensile load

- Large selection of common designs for

locking pins and retaining cams - Limited absorption of lateral forces due to the

use of metal guide rings - Retaining cams available with radial play

locking pins and retaining cams

use of metal guide rings

Series 50E8

- Max. tensile load 3700 N

- Tolerance compensation on the pivot due to space-saving disk springs

- Flat holding sock

- High preload

Series 2600/2700

- Max. tensile load 1330 N

- Small fastener for high tensile load

- Large selection of common designs for

locking pins and retaining cams - Series 2600: Cylinder head

- Series 2700: Countersunk head

locking pins and retaining cams

Series 50E21

- Max. tensile load 900 N

- Locking pin with plastic washer to protect

decorative surfaces - Spring-loaded retaining cams in snap-in and clip-on versions

- Snap-in guide ring for quick installation of the

locking pin without retaining washer

decorative surfaces

locking pin without retaining washer

Series 99F

- Max. tensile load 700 N

- Enlarged clamping thickness range

- Retaining cams with external thread can be screwed in directly

or fitted with a nut - Encapsulated design, splash-proof

or fitted with a nut

Series 5F

- Max. tensile load 670 N

- Locking pin with plastic washer

to protect decorative surfaces - Resilient holding socks

to protect decorative surfaces

Well advised with Benloc

You need a special offer or have a

question about one of our products?

Just give us a call. We will be happy to advise you.